Das Fachgebiet Industrielle Informationstechnik

Das Fachgebiet Industrielle Informationstechnik ist in das Institut für Werkzeugmaschinen und Fabrikbetrieb eingebettet und beschäftigt sich mit der Weiterentwicklung von digitalen Lösungen zur Verbesserung und Erweiterung der Tätigkeiten von Ingenieur*innen im gesamten Ablauf der virtuellen Produktentstehung von der Produktidee über die Produktentwicklung bis hin zur Planung und Anlaufabsicherung der Produktion.

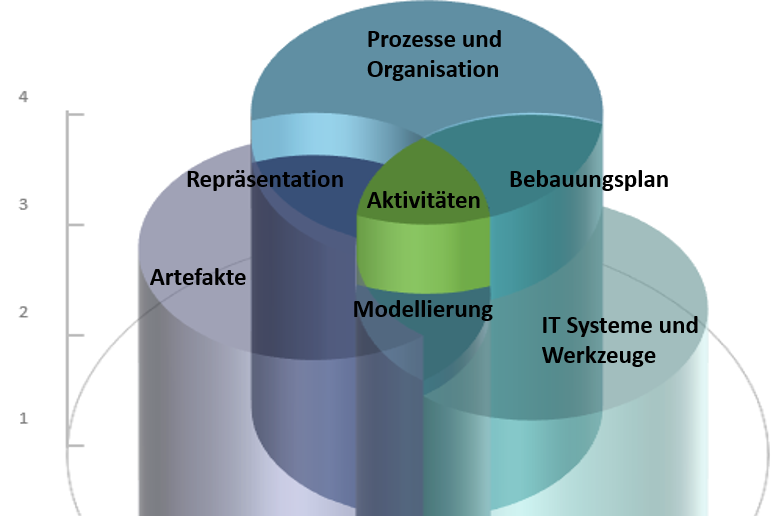

Ausgewählte Forschungsschwerpunkte sind die intuitive und kontextbezogene Informationsmodellierung, intuitiv bedienbare und funktional erlebbare virtuelle Prototypen, die funktionsorientierte virtuelle Produktentstehung sowie Entwicklungsprozesse und Methodiken für die Produktgestaltung. Das wichtigste Element des Lehrkonzepts unseres Fachgebietes stellen die ingenieurs- und informationstechnischen Inhalte dar, die es bedarfsgerecht zu lehren und zu vermitteln gilt. Dabei werden Kompetenzen, Erfahrungen und Werte für den Ingenieur*innenberuf nachhaltig vermittelt.

Unsere Mission & Vision

Ingenieur*innen sollen mit kreativer Virtualität und digitaler Kontinuität nachhaltiges Leben ermöglichen.

Wir virtualisieren die Produktentstehung durch Gestalten von Daten, Modellen, Methoden, Werkzeugen und Prozessen.

Wir verwirklichen neue digitale Entwicklungsintelligenzen als Teil eines soziologisch-technischen Systems für eine nachhaltige Zukunft.

Wir nutzen neuste Technologien der Informationstechnik sowie innovative Methoden der angewandten und experimentellen Forschung.

Damit steigern wir die Innovationskraft und Effizienz des Engineerings.

© pixabay

© pixabay